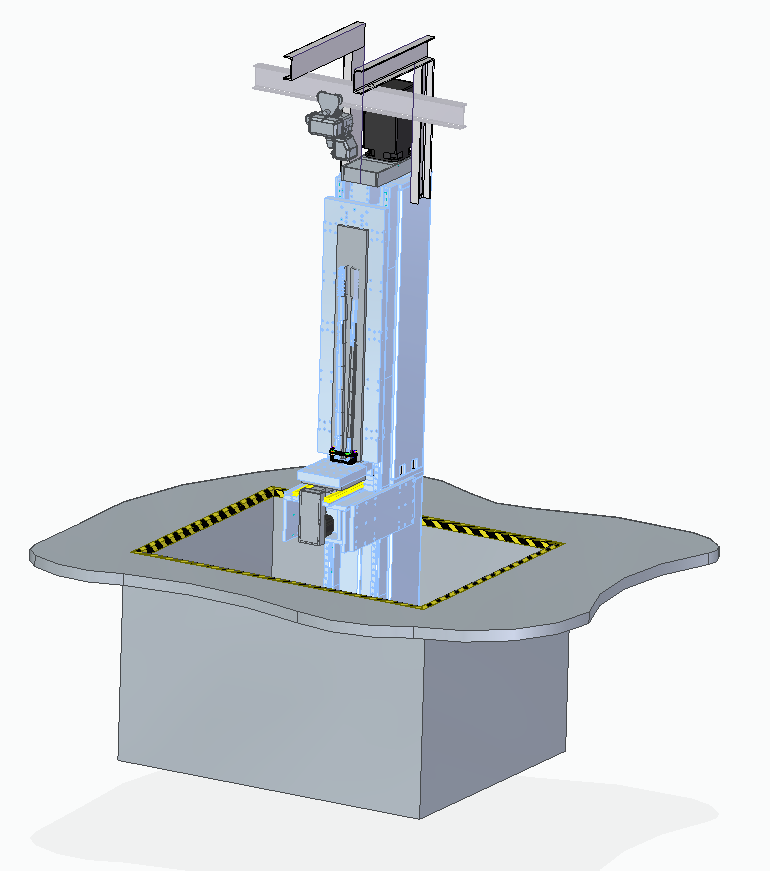

In January 2018, VAPOS began research and development of a CNC stretching machine. This project is co-financed by the European Union from the Operational Programme Enterprise and Innovation for Competitiveness. The aim of the project was to design a new original solution for the CNC broaching machine and to create two fully functional prototypes of these machines.

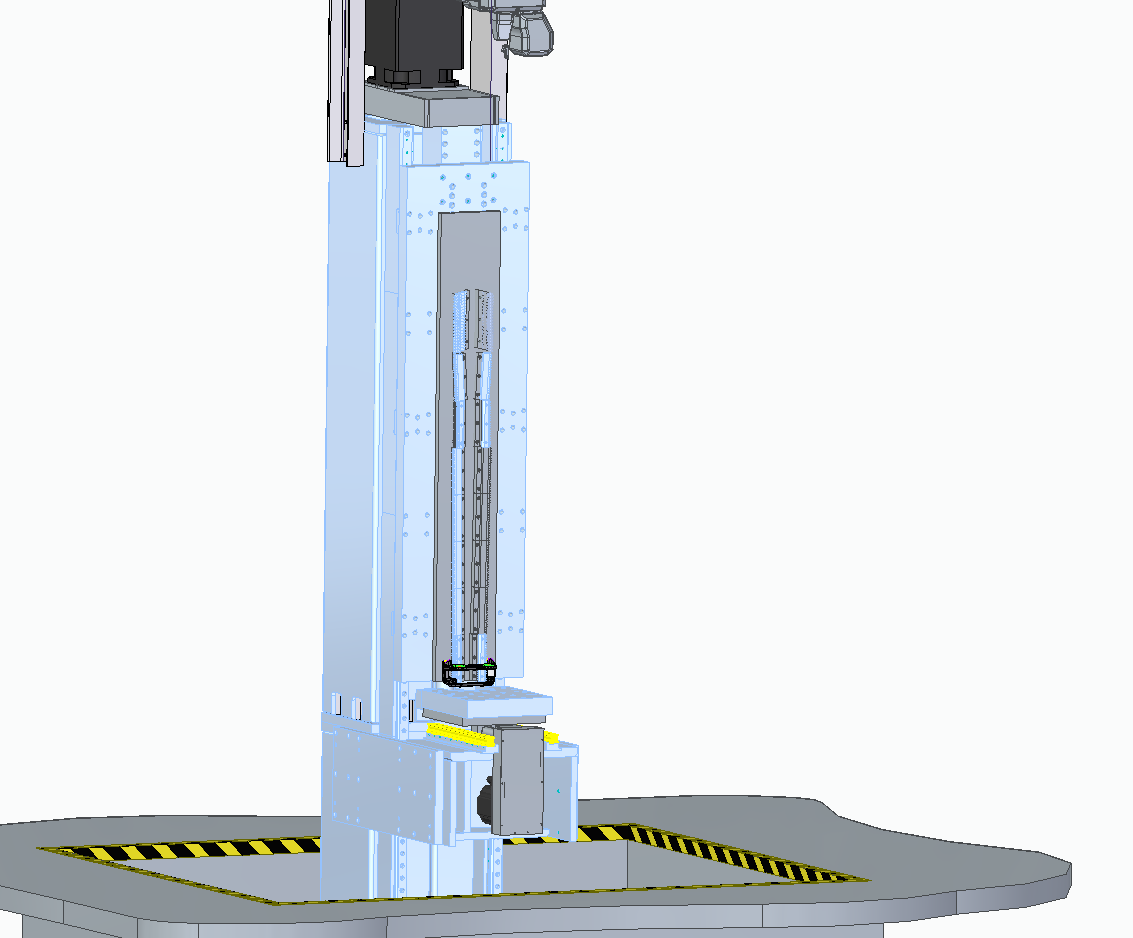

An important principle of the innovation is the replacement of the slide guide by a linear guide. With the linear guide, higher feed rates, higher accuracy of axis positioning and variable tool cutting speeds can be achieved. The hydraulic drive has been replaced by pre-tensioned ball screws, which allow the feed to be continuously controlled, so carbide tools can also be used. This drive method also allowed the unwanted machine frequencies, which are also a source of faster tool wear, to be filtered out.